Chemicals Bag Making Machine

The bag making process begins with the unwinding of a roll of kraft paper can be added with PE film, which is then guided through a series of rollers and guides to ensure it is properly aligned. The plastic film is then fed into the machine’s cutting section, where it is cut to the required size and shape using a rotary or flatbed cutter.

Chemicals bag making machines are designed to optimize bag production efficiency while ensuring high-quality, airtight, and leak-proof bags suitable for chemical products.

A chemical bag making machine is a specialized piece of equipment used in the manufacturing of bags for chemical products. These machines are designed to produce bags that can withstand the harsh environments and conditions that are often associated with chemical products.

The bag making process begins with the unwinding of a roll of plastic film, which is then guided through a series of rollers and guides to ensure it is properly aligned. The plastic film is then fed into the machine’s cutting section, where it is cut to the required size and shape using a rotary or flatbed cutter.

Once the plastic film is cut, it is then fed into the machine’s sealing section, where the sides and bottom of the bag are sealed using heat. The sealing process ensures that the bag is airtight and leak-proof, which is crucial for chemical products that can be hazardous.

After the sealing process, the bag is ready to be filled with the chemical product. The bag making machine can be customized to produce bags of various sizes, shapes, and thicknesses to suit the specific needs of different chemical products.

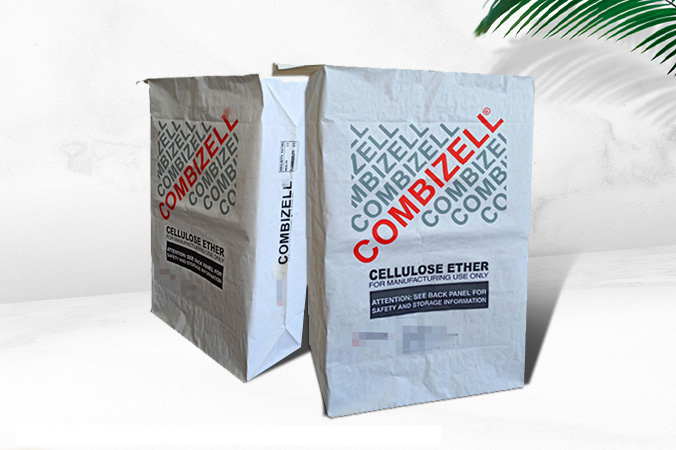

Some chemical bag making machines also have the ability to print product information, barcodes, and logos onto the bags during the manufacturing process. This is done using specialized printing technology that ensures the printed information is clear, legible, and resistant to smudging and fading.

Features of chemicals bag making machine

Roll-fed Design: Chemicals Bag Making Machines are designed to operate using roll-fed plastic film. The machine unwinds the roll of film and processes it through the machine to create the bag.

Cutting Mechanism: A Chemicals Bag Making Machine is equipped with a cutting mechanism that can cut the plastic film to the desired bag size and shape. Depending on the machine, the cutting mechanism may be a flatbed cutter or a rotary cutter.

Sealing Mechanism: To ensure that the bag is airtight and leak-proof, Chemicals Bag Making Machines feature a sealing mechanism. The sealing mechanism may use heat, ultrasonic welding, or adhesive to seal the bag.

Bag Size Adjustment: Most Chemicals Bag Making Machines have the ability to adjust the bag size according to the product’s specific needs. This feature allows manufacturers to produce bags of different sizes using the same machine.

Printing Capabilities: Some Chemicals Bag Making Machines are equipped with printing technology that can print product information, barcodes, and logos onto the bag during the manufacturing process.

User Interface: Chemicals Bag Making Machines come with a user interface that allows operators to control the machine and monitor the bag production process.

Safety Features: To ensure operator safety, Chemicals Bag Making Machines may feature emergency stop buttons, safety guards, and other safety features.

Maintenance: Some Chemicals Bag Making Machines are designed for easy maintenance and cleaning, with quick-change components that allow for easy replacement.

Overall, a chemical bag making machine is an essential piece of equipment for the production of bags for chemical products. These machines are designed to produce high-quality bags that are durable, airtight, and leak-proof, ensuring the safety of the product and the end-user.