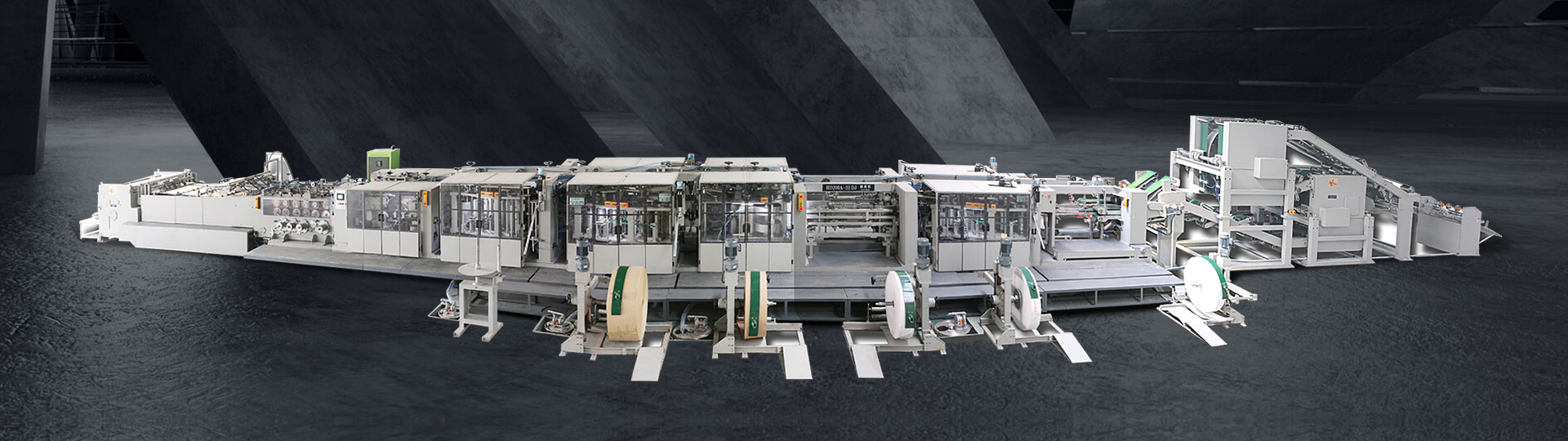

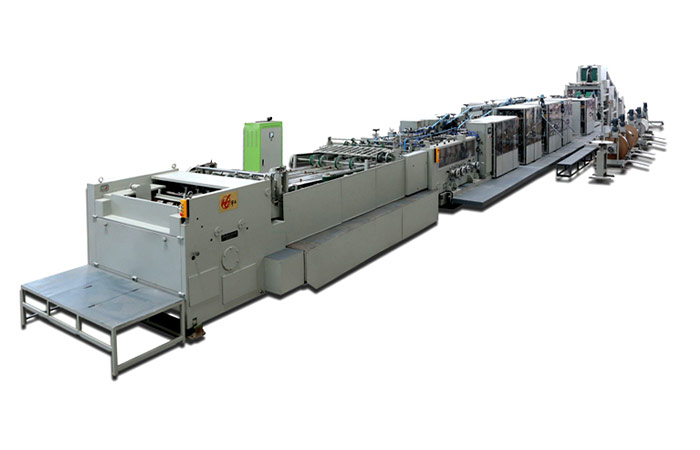

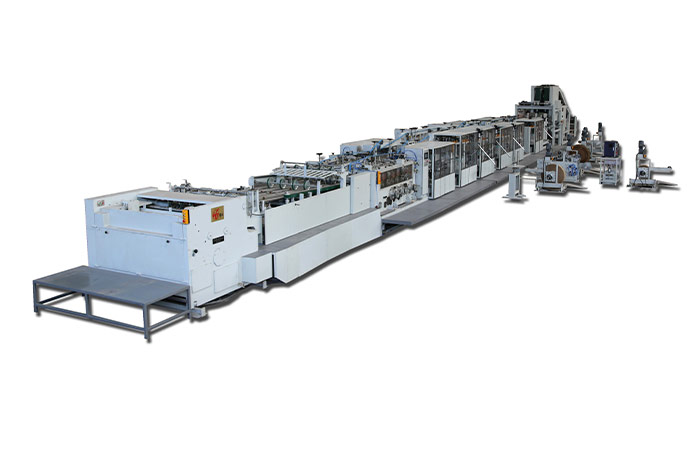

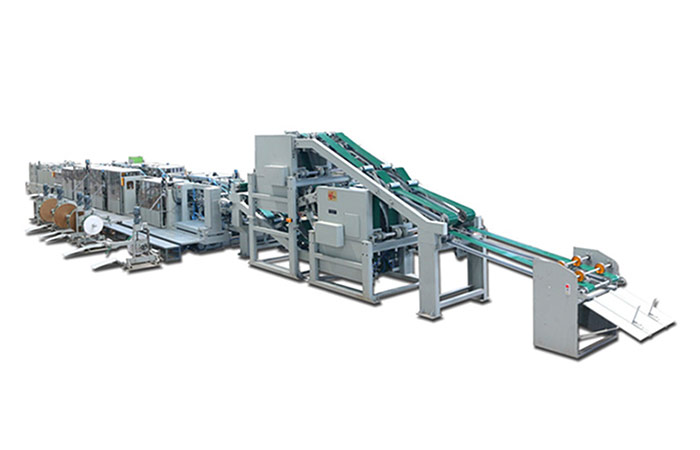

Square Bottom Machine

A square bottom machine, also known as a square bottom bag machine, is a type of packaging machine used to manufacture square bottom bags, typically made of paper or plastic materials. The machine operates by continuously feeding and forming the material into a tube, then cutting it to the desired length, and sealing the bottom to create a finished square bottom bag. These machines are commonly used in the food, chemical, and agricultural industries for packaging a variety of products, from flour and grain to chemicals and pet food.

The square bottom machine is a kind of equipment used to make valve bags. It seals the packaging bags tightly. It is usually used together with a tube making machine. This equipment integrates technologies such as photoelectricity, electromechanical, and pneumatic integration, saving labor. It saves time and plays a great role in improving production efficiency and saving capital investment for enterprises.

Square Bottom Machine Safety Operating Regulations

1. The discharge mechanism of the silo

The device is mainly based on the frame. The frame is equipped with a turntable, a turntable, a suction paper assembly arranged on the turntable, a silo, and a discharge mechanism; the silo and the discharge mechanism are arranged on both sides above the frame, and the silo and The discharge mechanism is located on the turning path of the turntable; the turntable includes disc bodies located at both ends and a mandrel connecting the two disc bodies.

2. Paper suction device

The suction paper assembly is rotatably installed on the two disks of the turntable, one of which is equipped with a transmission mechanism that drives the rotation of the paper suction assembly, and the other disk is provided with an air distribution mechanism for supplying air to the paper suction assembly; The paper assembly includes a hollow shaft, which is rotatably arranged on the two disc bodies of the turntable, and a number of paper suction wheels are sheathed on the hollow shaft.

The suction wheel is provided with a hollow rod body; the hollow rod body is provided with suction cups arranged along its length direction, the suction cups are connected with the hollow rod body, the hollow rod body is connected with the hollow shaft, and the hollow shaft is connected with the negative pressure device through the air distribution mechanism.

3. Insert the valve paper into the valve device

After the feeding device arranges the stacked paper bags neatly, it will inhale. After feeding, the paper bag will be folded and creased automatically by the folding and creasing device of the bottom paste machine, the valve paper will be inserted into the valve device, and the reinforcing strip will be pasted on the paper bag to complete.

The applications of square bottom machines are diverse and can be found in a variety of industries, including:

1. Food industry: For packaging food products such as flour, sugar, rice, pet food, etc.

2. Agricultural industry: For packaging agricultural products such as grain, seeds, fertilizers, etc.

3. Chemical industry: For packaging chemical products such as powders, granules, liquids, etc.

4. Pharmaceutical industry: For packaging pharmaceutical products such as pills, capsules, etc.

5. Building materials industry: For packaging building materials such as cement, sand, etc.

6. Retail industry: For packaging products sold in retail stores, such as toys, gifts, stationery, etc.

7. Logistics and distribution: For packing and shipping products, such as machinery parts, electronics, etc.

The use of square bottom machines offers several benefits, including increased production efficiency, reduced material waste, improved product protection, and a more aesthetically pleasing final product.