What are the operation steps of bag making machine

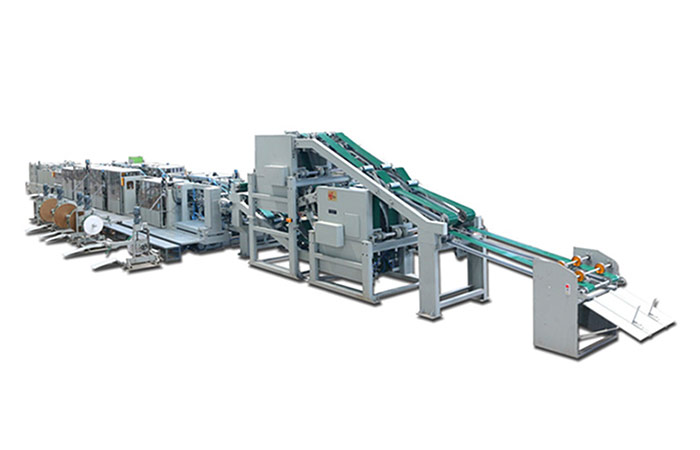

A bag making machine is a piece of equipment that is used to convert flat plastic film or sheeting into various types of bags, such as shopping bags, garbage bags, and food bags. The operation of a bag making machine typically involves the following steps:

Material feeding

The flat plastic film or sheeting is fed into the bag making machine through a series of rollers and guides. The material is typically fed from a roll of plastic film or sheeting.

Sealing

The bag making machine uses heat or ultrasonic sealing to seal the edges of the plastic film or sheeting together to create a tube of material.

Cutting

The tube of material is then cut into individual bags to the desired length. The cutting process can be done using a variety of methods, such as rotary cutters or guillotine cutters.

Folding and gluing

Depending on the type of bag being produced, the bag making machine may also fold and glue the bag at various points to create handles, closures, or other features.

Stacking and bundling

Once the bags are produced, they are typically stacked and bundled for easy transport and storage.

The operation of a bag making machine can vary depending on the specific type of machine and the type of bags being produced. It is important to follow the manufacturer’s instructions and safety guidelines when operating a bag making machine to ensure safe and efficient operation.