What are the specifications of paper tube machines?

Specifications for paper tube making machines can vary depending on the specific model and manufacturer. However, I can provide you with a general overview of the typical specifications you might find for such machines. Keep in mind that these specifications can change over time as technology advances, so it’s essential to check with the manufacturer for the most up-to-date information. Here are some common specifications for paper tube making machines:

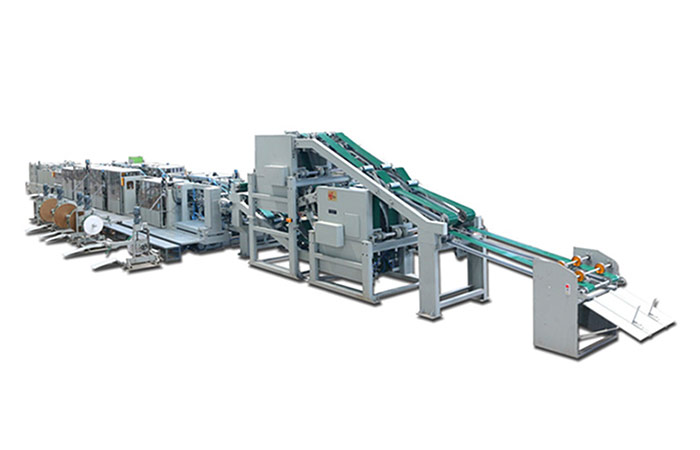

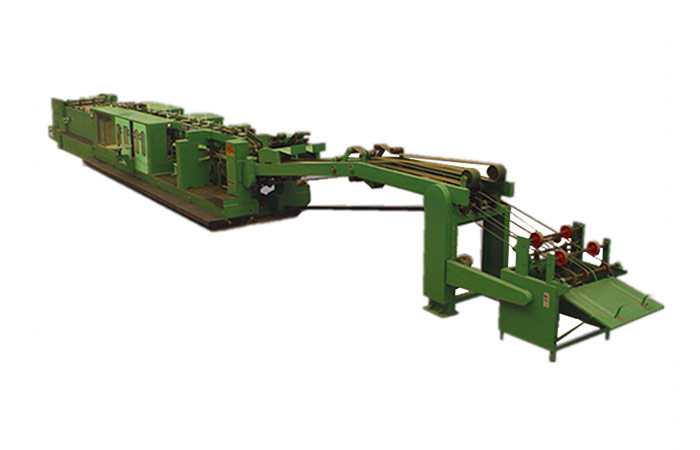

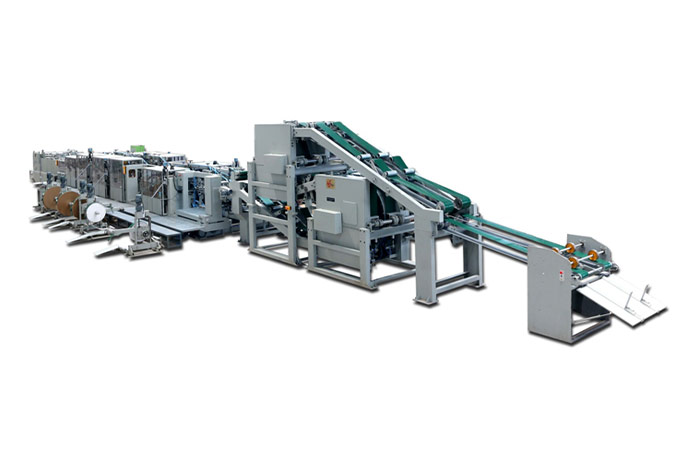

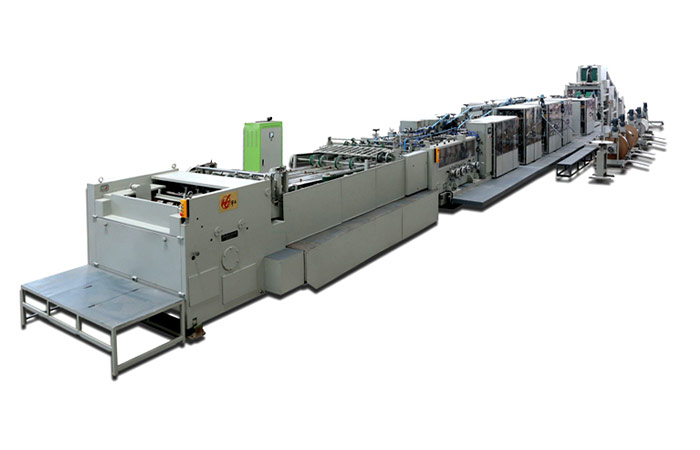

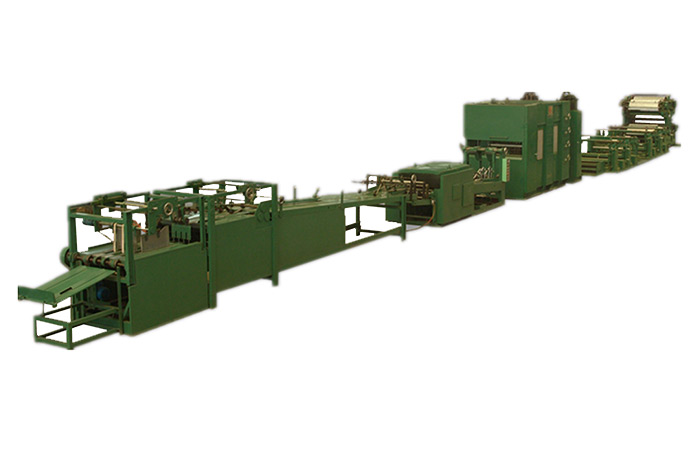

Machine Type: Paper tube making machines can be classified into various types, such as spiral paper tube machines, parallel paper tube machines, and composite can machines. The specifications may vary based on the type of machine.

Tube Diameter: The maximum and minimum tube diameters that the machine can produce. This can range from small tubes to larger industrial-sized tubes.

Tube Length: The range of tube lengths that the machine can produce. Some machines can produce long tubes suitable for various applications.

Production Speed: The number of tubes the machine can produce per minute or per hour. Production speed can vary significantly depending on the machine’s size and complexity.

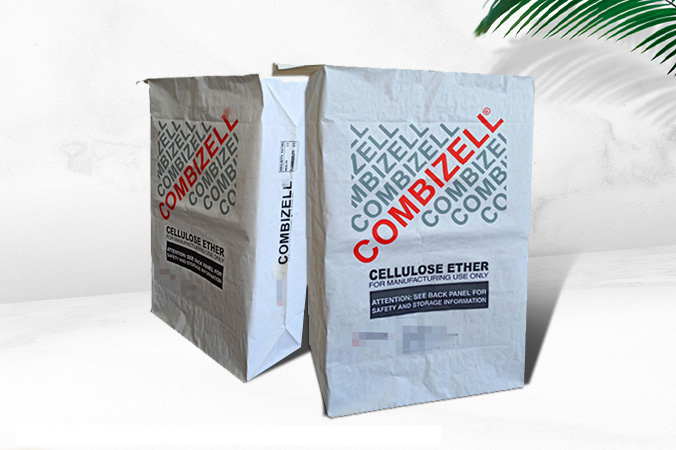

Raw Material Compatibility: The types of raw materials the machine can work with, such as kraft paper, paperboard, or composite materials.

Number of Plies: Some machines can produce multi-ply tubes by laminating multiple layers of paper together.

Gluing System: Information about the gluing system used for tube formation. This can include hot melt glue, cold glue, or other adhesive types.

Cutting System: Details about the cutting mechanism used to cut the tubes to the desired length. Some machines may use rotary cutters, while others may use guillotine-style cutters.

Control System: Information about the control panel and automation features, including touchscreen controls, PLC (Programmable Logic Controller) systems, and safety features.

Power Requirements: The electrical power requirements, including voltage, phase, and frequency, needed to operate the machine.

Machine Dimensions: The overall dimensions of the machine, including length, width, and height. This is essential for determining the space required for installation.

Weight: The weight of the machine, which is crucial for transportation and installation considerations.

Optional Features: Some machines may offer optional features such as embossing units, printing units, or additional customization options.

Warranty and Support: Information about the manufacturer’s warranty and available customer support services.

Compliance: Whether the machine complies with relevant safety and quality standards, such as CE certification.

Remember that the specific requirements for your paper tube making machine will depend on your production needs and the types of tubes you intend to manufacture. It’s advisable to contact manufacturers or suppliers directly to discuss your specific requirements and obtain detailed specifications for the machine that best suits your needs.