What are the performance of the paper tube machine

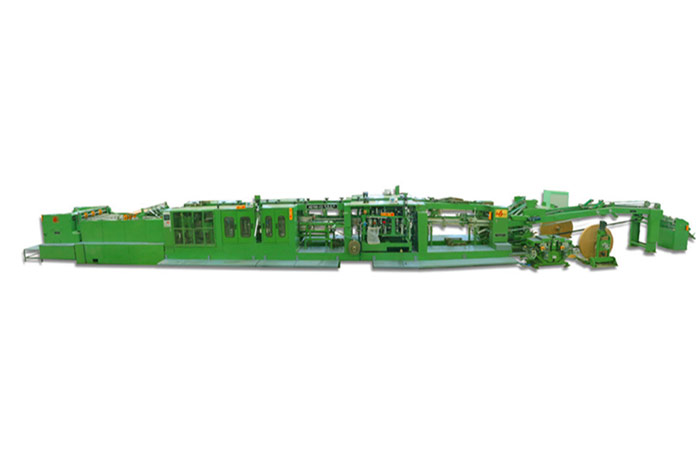

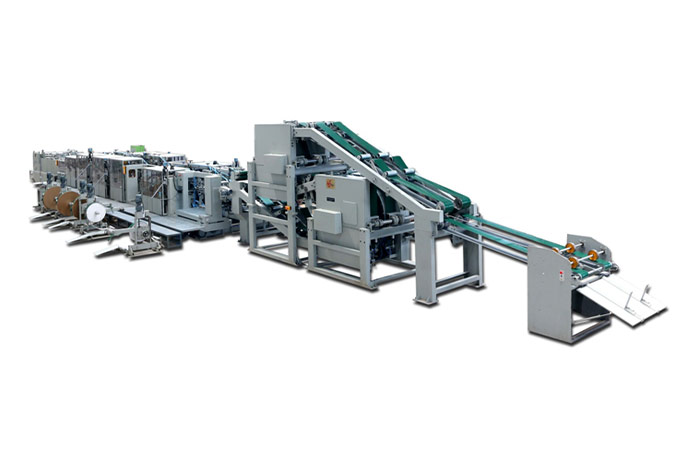

A paper tube machine, also known as a paper core machine or paper tube winding machine, is a manufacturing equipment used to produce paper tubes or paper cores. These tubes are commonly used in various industries, such as textile, packaging, construction, and paper manufacturing.

Paper tube machine performance

Tube Diameter and Length

Paper tube machines can be designed to produce tubes of different diameters and lengths, depending on the specific application requirements. The machine may have adjustable settings to vary the dimensions of the tubes produced.

Raw Material

Paper tube machines typically use paper or cardboard as the raw material. The machine may have mechanisms for unwinding paper rolls or sheets, which are then fed into the machine for further processing.

Gluing and Bonding

To form a solid tube, the paper is usually glued or bonded together. The machine may incorporate a gluing system that applies adhesive to the paper during the winding process. Different types of adhesives can be used depending on the application and desired strength of the tube.

Winding Process

The paper tube machine employs a winding mechanism to roll the paper into a cylindrical shape. It may have multiple stations or mandrels where the paper is wound, allowing for continuous production of multiple tubes simultaneously. The machine ensures proper tension control and alignment during the winding process to achieve uniform and well-formed tubes.

Cutting and Finishing

Once the paper tube reaches the desired length, the machine performs cutting operations to separate the finished tube from the winding mandrel. Additional finishing processes, such as trimming the tube edges or applying end caps, can also be integrated into the machine, depending on the specific requirements.

Automation and Control

Paper tube machines can range from manual to fully automated systems. Automated machines often incorporate programmable logic controllers (PLCs) and human-machine interfaces (HMIs) to control and monitor the production process. These features allow for precise control of various parameters, such as tube dimensions, glue application, winding speed, and cutting operations.

Maintenance and Safety

Regular maintenance and safety considerations are essential for efficient and safe operation of the paper tube machine. The machine should have safety features such as emergency stop buttons, guards, and interlocks to prevent accidents. Routine maintenance tasks, such as cleaning, lubrication, and inspection of key components, should be performed to ensure optimal performance and longevity of the machine.

It’s important to note that the specific features and capabilities of a paper tube machine may vary depending on the manufacturer and model. When selecting a paper tube machine, consider factors such as production capacity, tube specifications, automation level, and after-sales support to choose a machine that best meets your production requirements.