Solutions to common faults of bag making machines

The bag making machine is mainly used to process and produce packaging bags. It is easy to use and easy to operate, which brings more convenience to people. At the same time, various problems often occur during the use process. , and then we will give you a detailed introduction to the treatment methods for the more common problems.

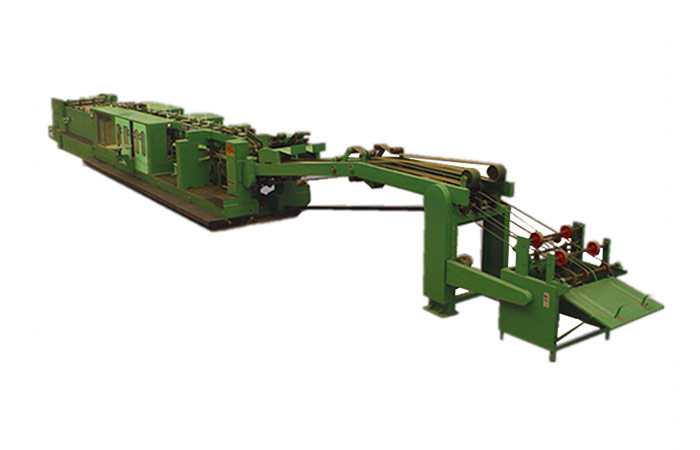

Main structural advantages of bag making machine

1. The bag making machine mainly uses ultrasonic waves and special steel wheels for processing. The sealed edge does not crack, does not damage the edge of the cloth, and is easy to use;

2. When the non-woven fabric is manufactured by the bag making machine, there is no need for pre-heating treatment, and continuous operation can also be performed;

3. The bag making machine has low cost and high efficiency, which is about 5 to 6 times faster than traditional machines, saving a lot of time;

Common problem

1. The stepper motor has abnormal noise when it is turned on, and the film cannot be fed.

Processing method:

(1) Check whether the main motor turns correctly and adjust it to the correct direction indicated by the arrow.

(2) Whether the stepper motor driver shows a fault, turn off the main power supply and turn it on again to return to normal.

2. During the working process, the length of the film feeding varies, the feeding size is more than 5mm shorter than the preset size, and the film is not fed once intermittently during the working process.

Processing method:

(1) The sensitivity of the photoelectric eye is not well adjusted or the polarity is not selected correctly.

(2) The photoelectric switch should be replaced due to leakage to ground or short circuit between terminals.

(3) When the discharging speed is lower than the feeding speed, it is necessary to relax each lamination bar, check the performance of the discharging part, and troubleshoot.

3. The torque of the stepping motor is obviously reduced, and the size of the bag is inaccurate.

Solution: The stepper driver is faulty, or the connection between the rubber roller and the stepper motor is blocked. Check and repair the stepper driver in time, and connect the rubber roller and the stepper motor.

4. Photoelectric tracking is inaccurate during bag making.

Processing method:

(1) The adjustment method and working state of the photoelectric eye are not selected correctly, and they should be adjusted correctly according to the requirements of the manual.

(2) The difference between the pre-adjusted film feeding length (when adjusting the blank bag) and the actual bag-making size is too large, and the length of the production line should be reset or the pressure and the device should be adjusted.

(3) If the resistance of the film is too large or the quality of the products in the previous process is poor, the materials should be checked and replaced.

5. The discharge speed is low or the work is not normal.

Processing method:

(1) The eye position switch is in poor contact or the cam angle is not good and should be adjusted or replaced.

(2) The thyristor or rectifier tube of the discharging speed control circuit board is broken down and should be repaired or replaced.

To sum up, this is all the introduction to the problem solving methods of bag making machine manufacturers, I hope it can help everyone. In fact, as long as the operation instructions are strictly followed in the paper bag process, these problems can be effectively avoided.

At the same time, in bag making, it is only necessary to follow the three elements of bag making, namely: pressure, temperature, and ironing time. When making bags (under the premise of ensuring ironing strength, relatively speaking) It should be low and the hot pressing time should be long. The hot pressing and sealing of the composite bag after this treatment will be beautiful, beautiful and straight.