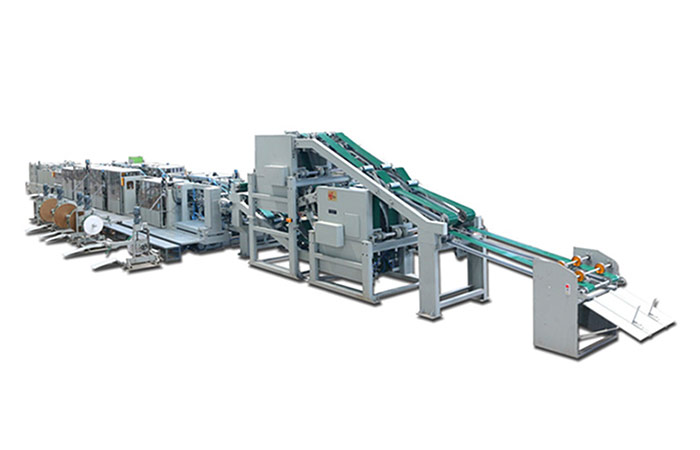

Advantages of valve bag filling process and automatic filling forming

Valve bags are mostly used for filling granular or powdery materials, which are used for loading and unloading bulk materials for convenient transportation. So do you know how valve bags are filled?

1. Valve bag filling process

The square bottom machine can use valve pockets to contain all kinds of fine powder and ultra-fine powder materials with low bulk density, strong air affinity, good or bad self-flowing properties.

The discharge port is unobstructed, the filling starts, the material enters the dividing wheel from the outer silo, and enters the ash hopper from the feeding port on the machine base. The material is evenly sent to the discharging port through the smooth rotation of the impeller. Lightly touch the travel switch on the right side of the material nozzle, the sealing cylinder shrinks, and the material falls into the bag smoothly.

Using the valve bag packaging machine, the material is evenly filled into the valve bag through the discharge seat, and then the filling amount is controlled by weight, and the sealing cylinder extends into the working state to seal the discharge port. That’s all for the valve bag filling process.

2. Advantages of automatic filling and molding of valve pockets

(1) The valve bag can withstand high temperature filling at 70~80℃ and dozens of handling turnovers.

(2) The surface of the bag is flat, smooth and beautiful, the pattern is rich in content, the color is clear, and it is anti-counterfeiting.

(3) It has good sealing, moisture-proof, waterproof and anti-fouling properties, and can be stacked in the open air for easy transportation and storage. The internal product does not melt, agglomerate, lose quantity or quality.

(4) The valve bag has a special formula, which will not soften and deform in case of high temperature, and will not rupture in case of severe cold; it is resistant to ultraviolet rays and has stable color; compared with plastic woven bags, it can double the storage and shelf life of outer packaging and inner products.

(6) The packaging capacity is flexible, and can be designed and manufactured according to the different requirements of different merchants for color, thickness and specifications, which can meet the needs of different manufacturers and different regions.

(6) Improve the packaging efficiency of valve bags and reduce labor intensity. Due to the use of automated packaging, the packaging speed is 3 to 5 times higher than that of traditional woven bag packaging, and the operator is reduced by about 75%.

(7) The packaging bag is easy to recycle and protect the ecology.

(8) With the application of new materials, the thickness of the film is gradually reduced, and the strength is gradually increased, and the comprehensive packaging cost of the valve bag is better than that of the traditional packaging form.

The above is the whole content of the valve bag filling process and the advantages of automatic filling and forming. The valve bag is relatively high in use in all walks of life. It is very convenient for the packaging and transportation of powdery bulk materials. The prospects are broad.