How much is the valve bag making machine

A valve bag making machine is a type of equipment used in industrial packaging to produce valve bags. Valve bags are a specific type of packaging often used for powdery or granular materials, such as cement, flour, chemicals, fertilizers, and more. These bags are designed with a valve or spout that can be opened for filling and then closed to seal the contents. Valve bags offer convenience, cleanliness, and efficient filling, making them popular for various industries.

The cost of a valve bag making machine can vary widely depending on several factors, including the brand, model, features, production capacity, and additional customization options.

Basic valve bag making machines might start at a few thousand dollars, while more advanced and high-capacity models can range from tens of thousands to several hundred thousand dollars or more. The complexity of the machine, the quality of materials used, and the automation features will all contribute to the overall cost.

Keep in mind that purchasing a valve bag making machine is an investment, and it’s important to consider not only the upfront cost but also factors like maintenance, operational costs, training, and potential technical support.

Valve bag making machines play a crucial role in the efficient and automated production of valve bags, which are widely used in industries that require hygienic and controlled packaging for bulk materials.

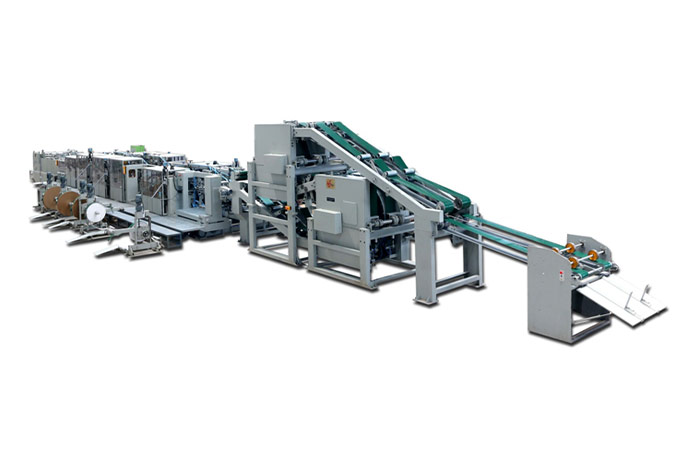

The valve bag making machine typically consists of several components and stages:

Material Handling and Unwinding: The machine starts by unwinding a roll of the packaging material (usually paper or plastic) that will be used to create the valve bags. The material is guided through the machine for further processing.

Printing (Optional): If required, the machine can include a printing section where information, branding, or labels can be printed onto the packaging material.

Cutting: The machine cuts the continuous sheet of material into individual bag blanks of the desired size. The cutting process may involve rotary knives, guillotine cutters, or other mechanisms, depending on the design of the machine.

Valve Application: This is a critical step where a valve or spout is applied to each bag. The valve is typically made of paper or plastic and is attached to the bag in such a way that it can be opened for filling and then sealed by folding, gluing, or heat sealing.

Sealing and Folding: The bag blanks are folded and sealed to create the final bag shape. The sides and bottom of the bag are sealed, leaving the valve or spout area open for filling.

Filling and Sealing: Once the bags are formed, they are conveyed to a filling station where the product is introduced through the valve. After filling, the valve is sealed, often using heat or adhesive, to secure the contents.

Curing or Drying (Optional): In the case of heat-sealed bags, a curing or drying process might be included to ensure proper adhesion of the seal.

Final Cutting and Stacking: The bags may undergo a final trimming or cutting process to ensure uniformity, and they are then stacked or bundled for further handling and distribution.

It’s important to note that the design and operation of valve bag making machines can vary based on factors such as the type of material being used, bag size, production speed, and specific features required by the packaging application. Additionally, some machines may have automation features, such as electronic controls, sensors, and programmable settings, to enhance efficiency and accuracy in bag production.