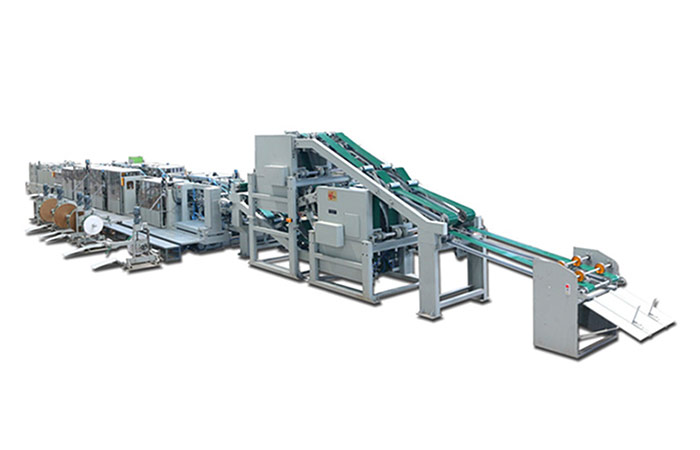

How does a bag making machine work?

A bag making machine is a type of machinery used to manufacture various types of bags, such as shopping bags, garbage bags, and food bags. The working principle of a bag making machine can be summarized in the following steps:

Material feeding

The machine is first loaded with a roll of plastic film or other material that will be used to make the bags. The material is unwound and fed into the machine.

Printing

If required, the machine can print the design or logo onto the material before it is formed into a bag.

Bag forming

The bag making machine then cuts the material to the required size and shape and folds it into a bag. The bag’s shape and size depend on the type of bag being produced and the machine’s configuration.

Sealing

The machine seals the bag by applying heat or pressure to the edges, creating a strong bond between the layers of material.

Cutting

Once the bag is formed and sealed, the machine cuts it from the rest of the material roll.

Collection

The finished bags are collected either automatically or manually, depending on the machine’s design.

Disposal

Any waste material or scraps are collected and disposed of properly.

Bag making machines can be configured to produce bags of different shapes and sizes, with various features such as zippers, handles, and vents. The process is highly automated, and the machine can produce a large number of bags quickly and efficiently, making it a popular choice in the packaging industry.