Installation and adjustment method of the bottom of the square bottom machine

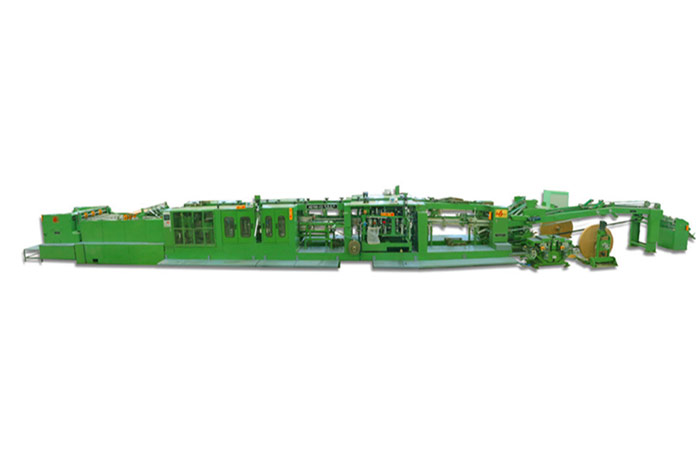

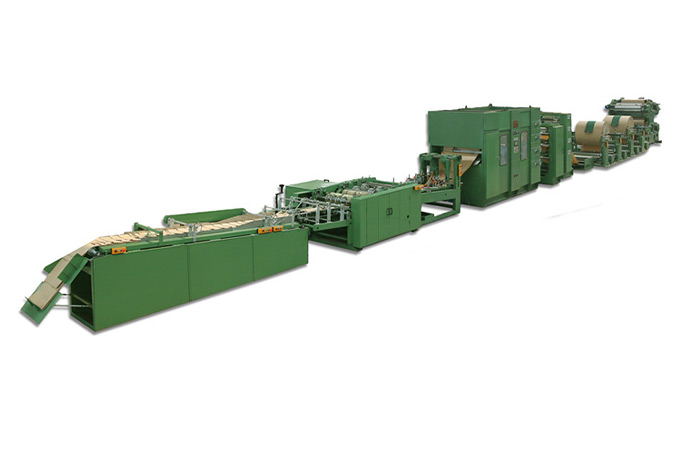

The square bottom bag is also called the paste bottom bag. The mouth can be sewn after filling. The open square bottom bag is widely used in the food industry. This kind of paper bag is produced by the square bottom machine. Then the installation and debugging of the bottom of the square bottom machine If you know the method, let’s take a look at it in detail.

Bottom installation of square bottom machine

1. Understand the attachment

There are many operating accessories at the bottom of the bottom paste machine, and the installation positions are also different. In order to master the operation skills of bottom stickers as soon as possible, you should memorize the names, installation positions and usage methods of various accessories. On this basis, it can be used flexibly. In order to change the paper shape at will in the future, various accessories can be quickly and accurately installed in place, and the bottom paste work can be completed with high quality.

2. Pull up and bend at the bottom

The folded corner of the paste bottom hook is at the cutting position of the straight line and the arc of the bending plate. When the bottom paste hook pulls up the bottom of the paper and bends it, immediately press and bend the bottom of the bottom of the paper. At the same time, the position of the lower support board should be adjusted so that the bottom sticker can be strongly supported when it is hooked to the bottom, and a special paper pressing rod should be installed so that the folded cardboard will not be left behind the bottom sticker hook and the pressing board. Rebound, after sizing and pressing by the sizing roller, it is smoothly fed into the folding part for folding.

3. Install the special platen

The role of the special platen in the bottom sticking operation is indispensable. Only by using a special presser rod can the bottom of the bottom sticker that is pulled up and bent will not bounce up, and can smoothly enter the folding part, and then the bottom sticker paste work is completed.

Square bottom machine adjustment

1. Die cutting pressure adjustment

Usually, the die-cutting pressure adjustment of the die-cutting machine adopts the upper adjustment method and the lower adjustment method, that is, the adjustment above the paper feed or the adjustment below the paper feed. Most of the die cutting machines use the upper adjustment, because from the From the technical point of view, it seems that if the two-seat die-cutting is adjusted downwards, it is difficult to keep the paper feeding at a level. For the same adjustment of the inclination of the die-cutting board, it is also possible to use the upper adjustment method.

2. Hook bottom attachment adjustment

The quality of the bottom paste is not only related to the bending quality of the bottom of the paper bag, but also whether it can be firmly bonded together is an important part of evaluating the quality of the paper bag. When all the hook bottom accessories are adjusted in place, according to the thickness of the paper and the elasticity of the cardboard, the gluing roller should be slightly lower or slightly higher than the cardboard paste (deviation ±0.5mm).

The above is the introduction of the bottom installation and debugging method of the bottom paste machine, I hope it will be helpful for you to operate the bottom machine.