What are the production control systems of the paper tube machine?

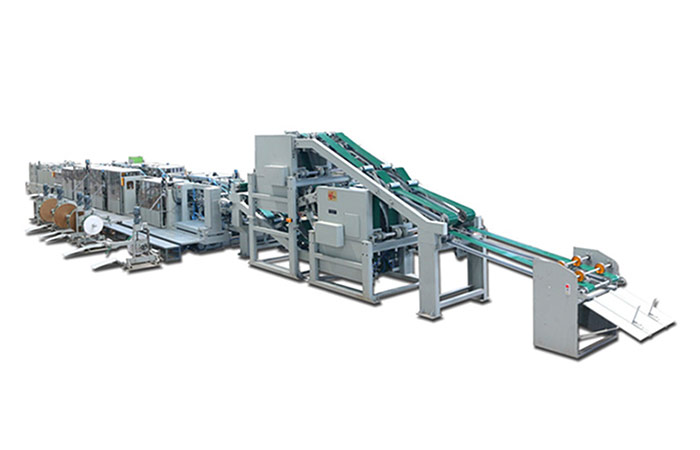

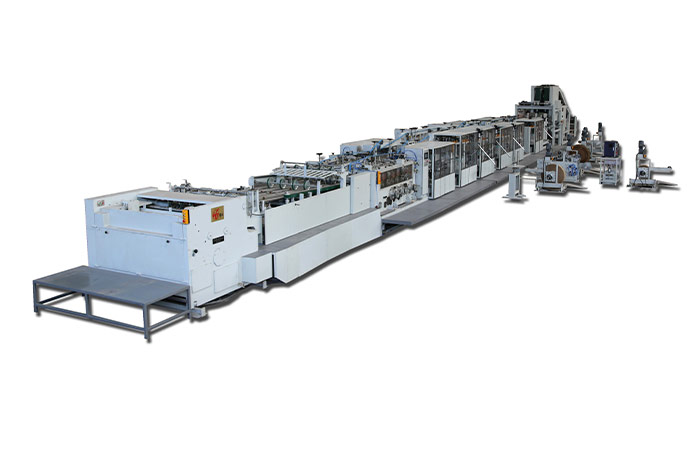

The high-speed automatic valve bottom paper bag paper tube machine is a linkage production line. The tube making machine is used to produce medium-sized stepped bottom bag tubes and straight-cut bag tubes. It needs to be used in conjunction with the bottom gluer to complete the entire valve bag. production process.

The bottom paste paper bag has low cost and high strength. It is widely used in the packaging of powdery and granular materials such as cement, chemical raw materials and grains. The paper tube machine is composed of multiple production control systems. Next, the paper tube machine manufacturer will introduce to you in detail what are its production control systems?

Features and functions of production control system of paper tube machine

1. Automatically correct the deviation of the paper

The paper feeding automatic deviation correction system is to make the paper edge of each layer of bag automatically run at the set position, to ensure the accuracy of the trapezoidal incision of the bag tube and the position of the glue, and it is an important automatic control function to ensure the quality of the bag tube and the glued bottom bag.

2. Automatic brake on paper break

When paper breaks occur at the paper holder, virtual cutting and the entrance of the main machine, emergency automatic braking is realized, which effectively avoids the phenomenon of traffic jam caused by untimely detection of paper breaks, shortens the processing time of paper breaks and reduces paper waste.

3. Bag cylinder output control

It realizes the automatic counting and grouping output of the bag tubes, and has the function of arranging the bag tubes, which lays a foundation for the bottom gluing machine to realize the fast bag tube feeding.

4. Printing coordination control

Coordinated with the start and stop of the main engine, the automatic ups and downs of the printing roller and the automatic switching of the ink distribution mode are realized to ensure the accurate and clear printing.

5. Frequency conversion speed regulation

The frequency conversion speed regulation makes the adjustment of the running speed of the equipment stable, fast, low noise and energy saving. The unique multi-point speed regulation control scheme allows the operator to operate the paper rack, printing machine and main engine in addition to the console. Carry out operations such as deceleration, parking and signaling to improve the operating efficiency of the equipment.

6. Automatic control of glue supply

After the paper bag is automatically glued by the layered virtual cutting and gluing system, the paper bag is formed into a bag tube shape.

7. Auxiliary control for paper roll replacement

Auxiliary control for paper roll replacement is provided, which can realize auxiliary replacement, add and supplement new paper rolls.

8. Automatic production statistics

The automatic output statistics can count the number of paper bags produced, which is convenient to understand the workload of the machine.

What are the production control systems of the paper tube machine? After reading the above content, you should have an understanding. The design of the production control system is concise and reasonable, and the operation is convenient and reliable. Personnel and power consumption ensure the high quality and low cost of the bottom bag product.