What is the difference between a valve bag and an open bag?

Valve bags are widely used at this stage and often appear in people’s daily life. The following square bottom machine manufacturers will popularize the difference between valve bags and open bags.

The difference between a valve bag and an open bag

1. Different definitions

(1) Valve bag

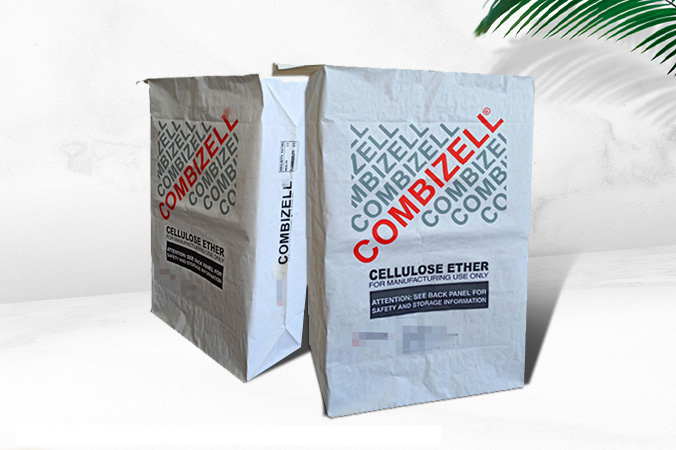

Valve bags, as the name suggests, have a “valve”. The bag body is sewn up and down, leaving a feeding bag (valve) for machine filling, and the packaged products are loaded into the bag from the filling port under the action of pneumatic or mechanical power.

The valve bag is further divided into an outer valve bag and an inner valve bag. The principle of the sealing method is that when the goods are filled, the contents will squeeze and seal the valve bag from the inside to achieve the purpose of sealing. The outer valve bag is filled with the material. It needs to be manually folded, and the inner valve bag is automatically sealed after the material is filled.

(2) Open bag

From the point of view of the bag itself, the open bag is a straight tube with a bottom bottom and no seal on the top. The packaged products are directly poured or put into the bag under the action of gravity, and are sewed and packaged by an industrial sewing machine. The various shopping bags, convenience bags and woven bags we usually use can be called open bags.

2. The production process is different

The processing technology of open bag and valve bag is different and the products suitable for packaging are also different. The valve bag packaging cost is high, and the packaging machine is also more expensive, but the weighing is very accurate, easy to stack, and because it does not need to be re-sealed, it saves a lot of human resources, making production more efficient, and the valve bag packaging is more beautiful, It also enhances the image of the product virtually.

The open bag packaging has low technical content, and it needs to be sealed again after the material is full, which requires a lot of labor costs. However, due to its low cost, it is also widely used in all walks of life.

3. Different production equipment

For different packaging bags, its packaging machines are naturally divided into valve bag packaging machines and open bag packaging machines. The valve bag packaging machine is an automatic quantitative packaging machine designed for various fine powder or ultrafine powder materials with low bulk density, strong air affinity, and excellent or poor self-flow.

It is mainly divided into: impeller packaging machine, spiral packaging machine, pneumatic packaging machine. The paper tube machine and square bottom machine produced by our company have rich experience in the production of valve bags, which can meet the requirements of different valve bag sizes and specifications.