How to choose a valve bag making machine

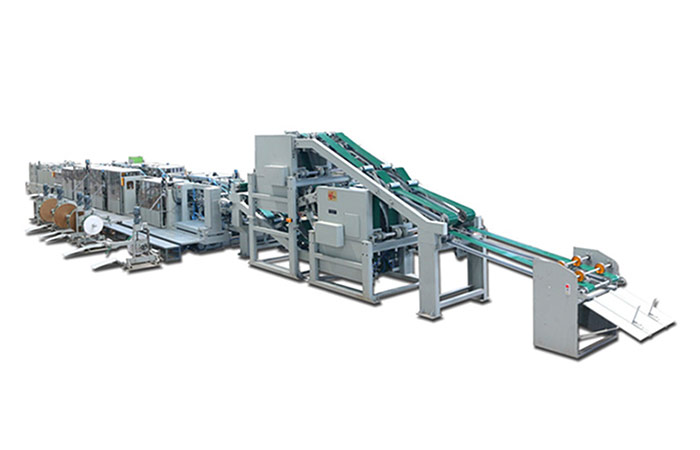

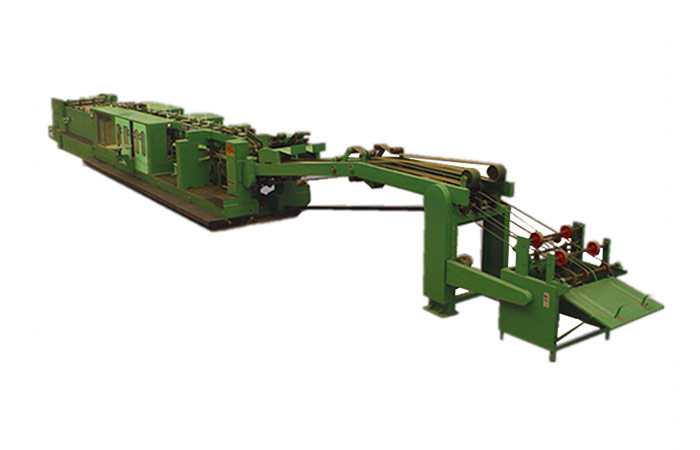

Choosing a valve bag making machine involves considering various factors to ensure that the machine meets your production needs, quality requirements, and budget. Valve bags are commonly used for packaging bulk materials like cement, chemicals, minerals, and agricultural products.

The key factors to consider when selecting a valve bag making machine

- Bag Size and Style: Determine the range of bag sizes and styles (e.g., dimensions, valve types) that you need the machine to produce. Some machines are designed for specific bag sizes, while others offer flexibility to accommodate a range of sizes.

- Production Capacity: Assess your production requirements in terms of bags per minute or bags per hour. Choose a machine that can handle your desired production rate while maintaining consistent quality.

- Material Compatibility: Consider the types of materials you plan to use for the bags. Different bag making machines are optimized for specific materials, such as paper, woven polypropylene, or other plastics. Ensure that the machine is compatible with your chosen bag material.

- Bag Quality: The quality of the bags produced is crucial. Look for a machine that can consistently produce bags with accurate dimensions, strong seals, and proper valve attachment. Quality control features like tension control and alignment systems can contribute to better bag quality.

- Automation and Features: Evaluate the level of automation the machine offers. Some machines come with advanced features like automatic tension control, servo-driven systems, and touchscreen interfaces for easy operation and precise control.

- Ease of Maintenance: A machine that’s easy to maintain and service can reduce downtime and maintenance costs. Look for features that simplify maintenance tasks, such as accessible components and user-friendly troubleshooting systems.

- Space and Installation Requirements: Consider the available space in your production facility. Choose a machine that fits within your layout and has suitable installation requirements.

- Supplier Reputation: Research and choose a reputable supplier or manufacturer with a track record of providing reliable and durable machines. Read reviews, ask for references, and assess their customer service and technical support.

- Training and Support: Ensure that the supplier offers training for your operators and provides technical support for any issues that may arise during machine operation.

- Cost: Compare the costs of different machines, keeping in mind that cheaper options may not always provide the best long-term value. Consider the machine’s efficiency, durability, and maintenance costs in relation to its price.

- Future Expansion: Consider your future growth plans. If you anticipate increasing production in the future, choose a machine that can be scaled or upgraded to accommodate higher production volumes.

- Regulatory Compliance: If your industry has specific regulations or standards for packaging materials, make sure the machine complies with those requirements.

- Customization: Some suppliers offer customization options to tailor the machine to your specific needs. If your requirements are unique, inquire about customization possibilities.

Before making a final decision, consult with multiple suppliers, request detailed specifications, and possibly visit their facilities to see the machines in operation. Carefully weigh all these factors to choose a valve bag making machine that aligns with your production goals and ensures high-quality bag production.