What is a square bottom machine? The components and processing flow of the square bottom machine

All kinds of packaging bags are commonly used in daily life, such as cement bags, mortar bags, chemical bags, food bags and other valve bags that are commonly used in the industrial field. Do you know how it is produced? They are all made by the square bottom machine and the paper tube machine.

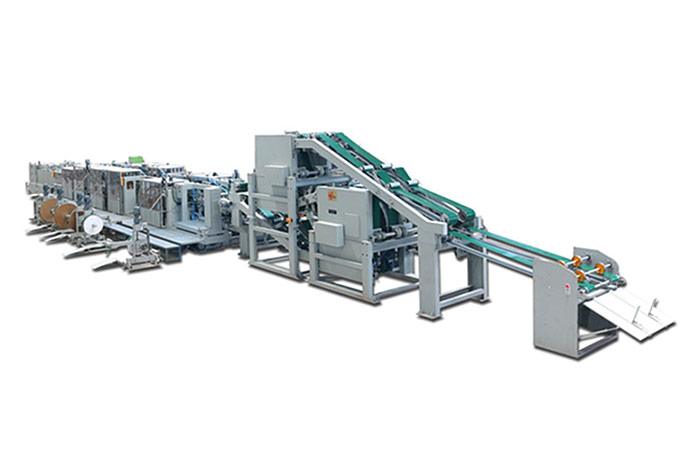

What is a square bottom machine

The square bottom machine is a kind of equipment used to make valve bags. It is used together with the paper tube machine. The two main equipment used to make valve bags adopts the integration of photoelectric, electromechanical and pneumatic technology, and is controlled by the photoelectric PLC automatic control system program finish. The square bottom machine has a paper tube machine that is responsible for unwinding and overprinting the bag body of the valve bag. The square bottom machine is responsible for the sealing of the valve bag. The bottom is opened through automatic gluing, bag tube conveying, valve opening strips, automatic gluing, and bags. Bottom turning and other processes are jointly produced to complete a valve bag. The square bottom machine can realize the processes of automatic feeding, gluing, and transportation, instead of manual operation, which greatly improves the production efficiency. At the same time, it can be more convenient and save a certain amount of raw materials.

The structure of the square bottom machine

1. Rotary bagging machine part ;

2. Straightening part (including double bag and diagonal bag removal) ;

3. Indentation, slitting, and opening ;

4. A valve port (including thumb port function, paper film dislocation function) valve port length 9cm-27cm ;

5. The second valve port part (including the cylindrical valve port and the hot melt adhesive intermediate seal), the valve port length is 9cm-27cm ;

6. Internal reinforcement part, internal steel bar length 20cm-35cm ;

7. Glue indentation part ;

8. Forming part ;

9. The length of the outer reinforcement part (cut after color code) is 25CM-40CM ;

10. Big S bag press system ;

11. Bag out position ;

12. Automatic order change function, waste bag detection and rejection function .

Square bottom machining process

1. Opening at the bottom of the bag

The opening of the bottom of the bag is determined by the parallel direction along the vertical wall at the end of the shoe upper, and the vacuum bag makes a downward horizontal reciprocating movement. The paper wings of the straw suction bag tube are splayed upwards and downwards at both ends. Rotate the claws and insert the opening tube into the bag. The end of the bag-pressing marking line forms a triangular bag corner. After pressing it to the next conveyor belt, the vacuum suction device and the claw opener can be adjusted by pasting width. Tighten according to specifications. Synchronous coordination of main conveyor belt, material suction and claw opening machine.

2. Sticky valve mouthpiece

The valve port of the bag tube starts to work from the paper reel, is guided to the correct path by the corrector, and is positioned and broken. From the plaster to the side of the bag tube opening wing at high speed, the electronic control system monitors the strip path. If there is a space or a paper bag at the location, the control system will order the strip to be cut. To be ruled out, the pasted wheel will not be pasted.

3. Automatic gluing

Before the bottom of the bag is formed, it needs to go through two gluing procedures. After entering the formed paper bag, the paper wings of the bag are folded in the opposite direction of the deformed end and the deformed plate. They are assembled on the core-wrap plate according to a fixed size, and run after the paste is discharged from the outer core, and they are firmly pressed by rolling.

BAG width adjustment: (1) Glue and paste on the valve position; (2) Wipe the paper wings horizontally, and make clear instructions in the electronic control system according to the set procedure.

The above is the introduction of the square-bottom machine. The size of the valve pocket made by the square-bottom machine varies according to different models, and the specific size setting is also carried out according to the needs.