Why are valve pocket packaging machines so versatile

In the current enterprise development, the manual production mode has been completely replaced by mechanization, so that the entire production can be improved unprecedentedly, and the high-efficiency production process is also more standardized and unified. The advancement of technology and the popularization of mechanization have achieved the driving force for the development of many industries. The valve bag packaging machine has achieved a wonderful leap with the help of technology and has become one of the necessary equipment for commodity filling.

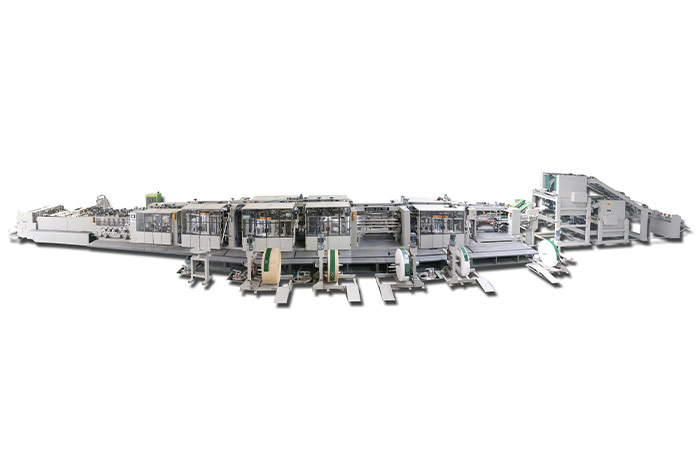

The valve bag packaging machine is the product of modern technology, which represents the realization and progress of global industrialization. According to the needs of the market, today’s valve bag packaging machines are divided into many small branches, and each has its own unique functions and characteristics, and the degree of automation has also been upgraded. The types of valve bag packaging machines currently on the market are: impeller type valve port Packaging machines, spiral packaging machines, pneumatic packaging machines, vacuum powder packaging machines and other products; they have unique uses in various industries, helping entrepreneurs to complete product packaging with good packaging quality and high efficiency.

The valve pocket packaging machine is an automatic quantitative packaging machine designed for various fine powder or ultrafine powder materials with low bulk density, strong air affinity, and excellent or poor self-flow.

The working principle of valve bag packaging machine:

1. The valve bag packaging machine uses the motor as the power source to drive the impeller in the discharge seat to rotate smoothly to achieve uniform feeding;

2. The sensor measures the weight of the material in the bag and inputs the measurement signal into the microcomputer. When the filling weight requirement is met, the microcomputer outputs the signal, and the sealing cylinder extends into the working state to seal the discharge port;

3. At the same time, the pull rod of the electromagnet moves up, and the material bag falls, so as to realize quantitative and rapid packaging of loose materials;

4. The material enters the grid wheel from the outer silo, and enters the ash hopper from the feed port on the machine base. The material is evenly sent to the discharge port through the smooth rotation of the impeller, insert the packaging bag, and lightly touch the travel switch on the right side of the feed nozzle. , the sealing cylinder shrinks;

5. The discharge nozzle is unobstructed, the filling starts, and the material falls into the bag smoothly;

6. With the increase of the material in the bag, the signal input by the sensor to the microcomputer is also constantly changing. When the weight of the material reaches the set requirement, the microcomputer outputs the signal, the sealing cylinder extends, and the discharge port is sealed. Move, the material bag falls, so as to achieve the automatic packaging requirements of automatic measurement and automatic bag drop.

The valve bag packaging machine not only improves work efficiency, but more importantly, saves costs and has a wide range of applications. Especially now that the difficulty of recruiting workers is a big problem, the labor efficiency is low, and the work enthusiasm is poor. The valve pocket automatic packaging machine has solved these practical problems for enterprises.

In the process of development, the valve bag packaging machine is constantly innovating, opening the way to new fields, daring to be the pioneer in the new direction of the market, and providing more convenient services for our customers. Facts have proved time and time again that Hawo Technology’s valve pocket packaging machine has taken correct measures and followed the pace of the times. The valve pocket packaging machine that can survive in the market still proves that it has withstood the test of the market.