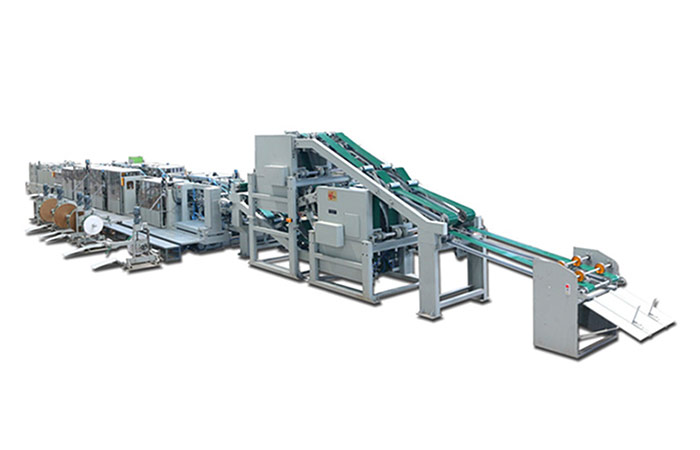

What is the operating procedure of the valve bag packaging machine

As the name suggests, the valve bag packaging machine is used to produce valve bags. Generally speaking, the main operating procedures are mainly divided into two parts, namely pre-production inspection and packaging. If you are familiar with these two parts, you will be familiar with how to operate, but during operation, Some things need to be paid attention to, otherwise problems are prone to occur.

1. Check

(1) Check that the selector switch is in the manual position before power-on;

(2) After power-on, observe that the weighing instrument is at the normal zero position;

(3) Check that the pressure of the control gas source is 0.5mpa, and the pressure of the fluidizing gas source is 0.05mpa.

2. Packaging

The selector switch is switched to the automatic position, the packaging bag is clamped, and the packaging machine automatically completes the following functions: opening the feeding butterfly valve → closing the feeding butterfly valve → start of fluidized discharge → end of fluidized discharge → lift up the bag clamping cylinder → turn over the bag → Next cycle.

Manual: for manual discharge and reset;

Automatic: normal packing;

Clearance: used in the last few packs or when the material is blocked;

The meaning of the indicator light:

(1) The feeding indicator light is on, indicating that the feeding butterfly valve has been opened, and the material enters the fluidization bin of the valve bag packaging machine from the large silo.

(2) The discharge indicator light is on, indicating that the feeding butterfly valve has been closed, the fluidization valve and the fast and slow discharge valve have been opened, and the material enters the packaging bag from the fluidization bin.

3. Precautions

(1) When there are unexpected situations such as material spraying and hand clamping, please press the emergency stop switch quickly, and the packaging machine will cut off the power supply;

(2) Cover the packaging bag as required, and the bag head should completely press the packaging bag after clamping the bag to avoid material spraying;

(3) When the automatic bag turning is unsuccessful, you can directly press “manual bag turning” to assist;

(4) If it is found that the feeding butterfly valve does not close all the time when feeding, it means that there is no material in the large silo, please switch to the clearance mode to pack the next few packages of materials;

(5) When packaging in automatic mode, if there is swelling bag and large dust in the packaging bag, please adjust the pressure of the fluidizing gas source appropriately; when packaging in automatic mode, if there is slow discharge and blocking, please adjust the pressure of the fluidizing gas source appropriately. The source pressure or the stroke of the slow discharge cylinder should be appropriately increased; when the packaging bag is seriously swollen in the clearance mode, it means that the material in the fluidized warehouse has been emptied;

(6) Before leaving get off work every day, clean up the residual materials in the fluidized warehouse and the dust on the scale body, switch the selector switch to manual mode, and press the emergency stop switch to cut off the power supply.

The above is all about the operation of the valve bag packaging machine. In the daily operation process, you must strictly abide by the corresponding operating rules, otherwise it is easy to cause machine failure.